|

| |

|

MILLING |

| |

|

We are known for our powerful milling tools. You can machined small parts as well as big components, which needs realy big tools. We launched periodicly new milling tools and indexable cutting inserts, which meet the demands of modern machining. We develop our tools in cooperation with the biggest companies from diferent areas of metal chip machining. Join the group of satisfied users of our tools, which offer performance and reliability in all conditions. |

| |

Indexable Cutting Inserts

Beside the tools, the UP!GRADE milling solution assortment also contains a wide range of indexable cutting inserts. There are a lot of materials and geometries available. The new generation of UP!GRADE grades have been placed into the assortment. In the field of milling, these are the MT-CVD coatings –M9315, M9325, M9340 and M5315. The MT-CVD line has been completed with indexable cutting inserts coated with the |

|

|

PVD method (M83xx line for copy milling; 82xx line for general milling).

You should not miss

TheMT-CVD grades with coatings are the most productive grades in milling. The M5315 grade is determined for milling of cast irons and light milling of heat-treated steels. The M93xx line is determined for universal use. The M9315 grade is determined for milling with high cutting speeds under the stable conditions; the M9325 grade is a tougher version. The toughest grade of the M9340 line is determined for milling under less stable conditions and especially for milling of corrosion-resistant steels.

The grades with PVD coatings are characterised with high flexibility. The8230 and 8240 lines are the most universal grades. The indexable cutting inserts made of this grade are able to machine soft steel, corrosion-resistant steels, heat-resistant steels as well as cast irons with a high number of impurities in the surface skin. The8240 grade is determined for the toughest cutting conditions and for very tough materials. We recommend using the 8215 grade for stable conditions and for milling of heat-treated steels and cast irons. M8310, M8325 and M8345 are entirely new grades, which replace the older line of grades for copy milling – 7010, 7025 and 7040 and others.

We offer our customers modern geometries of indexable cutting inserts hand in hand with productive grades. These are specified with F letter (fine and finishing milling), M (universal use) and R (rough milling). |

| |

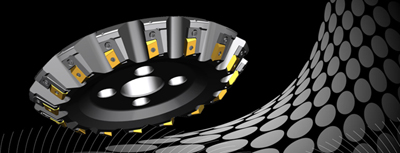

| Face Milling Cutters |

| |

|

The assortment of face milling cutters consists of the tools for plain milling (κr 45° to 75°). You can find here versions for productive and general milling. The assortment is completed with the offer of milling cutter for heavy rough milling (κr 57° and 60°). There are face milling cutters available from Ø 20 mm to Ø 315 mm in the offer according to the type and size of the indexable cutting insert. Shoulder and copy milling cutters (especially high-feed milling cutters) can also be used in this field. |

|

shade of the coating. These are four-facet solid drills with polished helical, which provide high accuracy of drilled holes and quality of their surface. The parameters and productivity of this line of drills will satisfy even the most demanding customer.

The offer of solid drills has been completed with a line for drilling of corrosion-resistant steels (M material group), which is suitable for soft steels, difficult-to-machine materials (S group) and easy-to-machine alloys of non-ferrous metals (N group). |

| |

You should not miss

One of the most productive face milling cutters are the tools with the HNGX 09 indexable cutting inserts, which have 12 cutting edges. They are offered in 2 sizes (HNGX06 andHNGX09) and 3 geometries, therefore they can be used for roughing to finishing.

The HNEF and HNMF indexable cutting inserts with 12 cutting edges for milling of cast iron have been placed into the offer of face milling cutters. There are 2 lines of milling cutters with a high and very high number of teeth, which ensures a high productivity of the tools.

Currently, new tools for light operations and for machining of corrosion-resistant steels, difficult-to-machine materials (DTMM) and soft low-carbon steels have been placed into the offer. These are the tools of the MULTISIDE family and also milling cutters for SEET09 and SEMT09 inserts.

The Penta HD milling cutters complete the offer of heavy roughing. They represent an economical version for depths of 5 to 10 mm and compete with their performance with tangential milling cutters. |

| |

Shoulder Milling Cutters

The 90° tools with one row of indexable cutting inserts for slot milling and shoulder milling from small depth (from milling cutter diameter of 10 mm) to the area of heavy roughing (up to diameter of 260 mm) are placed into this section. Productive milling cutters for Al and Al alloy machining with PKD (polycrystalline diamond) cutting inserts are also a part of this section. |

|

|

| |

You should not miss

The tools and LNGX12 and LNGU16 cutting inserts have newly been added into the assortment for the field of economical 90° milling. The tools withLNG inserts are especially determined for shoulder milling and face milling. The tools with LNGX inserts can also be used for ramping into material, helical interpolation or perpendicular recessing into material.

The milling cutters with ADMX 11 and ADMX 16 inserts belong to the new generation tools. These inserts are characterised by significantly lower cutting force, improved solidity of the insert cutting edge and perfect stability even under unfavourable cutting conditions. A great advantage of ADMX inserts is a wide spectrum of operations, for which they can be used – quick ramping into material, helical interpolation or perpendicular recessing into material.

The tools for milling of aluminium and aluminium alloys and other non-ferrous materials are suitable not only for shoulder milling but also for plain milling operations. Application possibilities are given by the type of the XOEN 12 insert used. The maximum allowed cutting speed of 7 000 m/min enables to achieve very high productivity of work and thus to minimise the machining time. |

| |

| Copy Milling Cutters |

| |

|

The copy milling cutters are tools with indexable cutting inserts with round cutting edges. It is either fully round cutting edge (indexable cutting inserts for toroid or ball nose milling cutters) or partially round cutting edge (from HFC milling cutters to radius versions of ADMX 11 and ADMX 16 indexable cutting inserts). The segment of copy milling cutters includes shell-type milling cutters, milling cutters with cylindrical clamping shank, Weldon-type chunk and modular (screw) milling cutters. |

|

| |

You should not miss

So-called HFC (High Feed Cutting) milling cutters are getting ahead in the field of rough copy milling nowadays. Pramet offers 2 types of HFC milling cutters. The HFC milling cutters with ZDCW 12, ZDEW 09 andZDEW 07 inserts for feeds up to 3, 2 and 1 mm per a tooth. They are especially irreplaceable during machining with big protrusion of a milling cutter. At such operations they go beyond copy milling and are considerably more productive than face milling cutters. The tools are suitable for milling of soft as well as heat-treated steels and cast irons.

ThePenta HF milling cutters with PDxx 09 inserts, which were optimised for milling of corrosion-resistant steels, difficult-to-machine steels and heat-treated steels, have newly been placed into the assortment. The cutting inserts with a transition edge are suitable for plain operation, the indexable cutting inserts with a radius edge represent the first choice for all other versions of use. The milling cutters with round inserts, e.g. RDHX or RCMX are getting ahead especially at the finishing operations on the stable machines and workpieces. Another advantage for the programmers is freedom of use during multi-axis machining (3D and more).

The assortment has also been enlarged by 2 versions of the ball nose milling cutters, which are suitable for milling of all groups of the machined materials. The universal milling cutters with ZP10 to ZP50 inserts with diameters of 10 to 50 mm. And the semi-roughing and finishing milling cutters of the MULTISIDE XP family in diameters of 16 to 32 mm. |

| |

Cylindrical Milling Cutters

The assortment of cylindrical milling cutters includes milling cutters for milling of deep shoulders and slots. The cylindrical milling cutters are determined for middle productive and productive milling machines. The milling cutters for milling of angular planes are also a part of the assortment of milling cutters. The adjustment angles correspond to the angles, which are most often used for |

|

|

| weld preparation. Cylindrical milling cutters with soldered cutting edges are also available for finishing operations. |

| |

You should not miss

The face milling cutters with SDGX 12 inserts (or SDMX 12 inserts) are new tools in the offer of peripheral milling. These full-cut milling cutters are determined for middle machining of steels from structural steels to corrosion-resistant steels, but also difficult-to-machine materials of S group.

The face milling cutters with ADMX 11 inserts have become a bestseller. They can be characterized by stable placing of the insert and very good chip evacuation. Ramping and helical milling are possible with these milling cutters. They are suitable for milling of all types of steels, cast irons and milling of non-ferrous metals according to the insert geometry chosen.

There are newly designed milling cutters with LNET16/SNGX13 inserts in the offer for the heaviest operations of machining steels and cast irons. The milling cutter is fitted with the LNET16 two-edge inserts on every other tooth on the face and the SNGX13 8-edge inserts are fitted on the rest of the milling cutter. There are also milling cutters with ISO 50 taper for automatic (ISO69871 and JIS B 6339) and manual (DIN 2080) replacement in the offer. The milling cutters with ISO 50 taper are made with an exchangeable front part.

The milling cutters for milling of areas for welds or other bevels also represent a favourite type of tools. The milling cutters for chamfering have the cutting edge length about 27 mm and we offer them within the angle adjustment from 15° to 75°. The milling cutters can also be used for fast evacuation of the material during plain milling (milling cutters with 15°) or for form slot roughing. |

| |

| Disc Milling Cutters |

| |

|

Disc milling cutter is one of the most productive milling tools. The innovated line of disc milling cutters is based on tangentially clamped indexable cutting inserts. Thus we can offer a productive and reliable solution for wider cut (adjustable milling cutters) and milling cutters for thinner holders (fixed milling cutters). |

|

| |

You should not miss

The fixed milling cutters are not only used for slot milling but also for material division. The milling cutters with flange can mill slots at the bottom of the part. The milling cutters are clamped in the same way as the standard shell end milling cutters. Disc milling cutters without flange can be used independently but also in assembled tools. For independently clamped disc milling cutters we offer FMH4 type arbor, which is universal for all widths of milling cutters offered.

Adjustable disc milling cutters represent a universal solution for slot milling. The exchangeable cartridges are adjustable within 14 to 18.5 mm, 19 to 24.3 mm and 24.5 to 30.5 mm according to the body of milling cutter and cartridge. The milling cutter bodies can also be one-side fitted for milling of one surface.

Feed per tooth, or middle thickness of hm chip, which should be between 0.1 to 0.2 mm for fixed and 0.08 to 0.1 mm for adjustable disc milling cutters are also important parameters when choosing the cutting conditions. |

| |

Solid End Milling Cutters

A wide assortment of solid end mills cutters covers all areas of machined materials. There are versions for all milling operations from roughing to finishing operations including milling cutters with universal use. The most used types of milling cutters are available in several length versions. |

|

|

| |

You should not miss

The most universal line of the solid end mills cutters is SUMA milling cutters. They have positive cutting geometry and very wear-resistant coating. Such combination enables them to machine in a wide range of materials of P, M, N and S groups.

The most productive type of the solid end mills cutters is roughing end milling cutter. They have divided cutting edge and differential pitch. This means smooth running in the cut, good chip evacuation and long life.

A record holder in face milling is HFC milling cutter RARU. High feed geometry of inserts and a great number of teeth place it among the most productive tools of its type in the market. |

| |

| Special Tools |

|

We launched every year hunderts of new products, but they are not always to meet your requirements. Therefore, we are ready to design and produce special tools for machining of complicated application as well as tools to reach faster machining cycle. We compile for you complete solution.

What you can expect from us:

- fast answer to Your request

- simple order

- delivery in agreed term

- complete construction tool information |

|

| |

| |

|

| |